Craftsmanship in Production

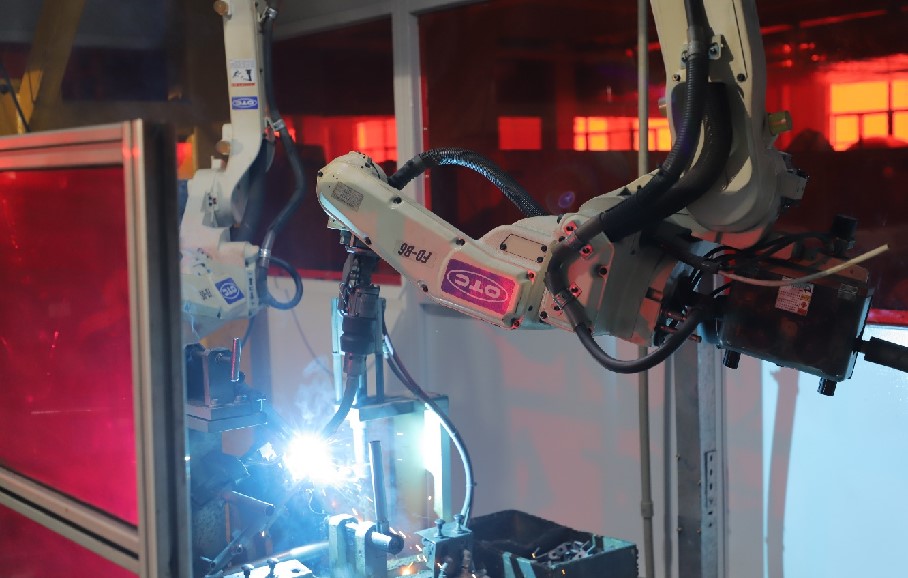

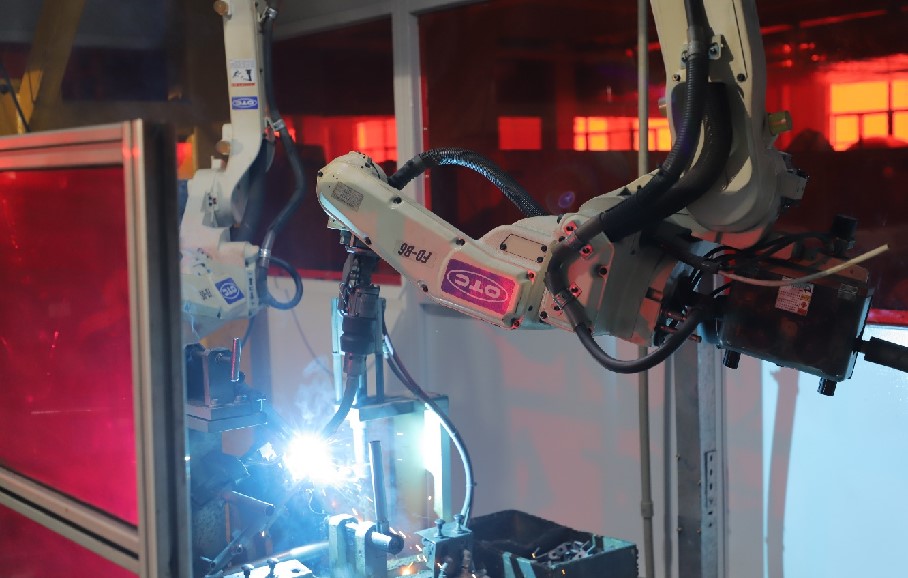

Fully intelligent production line, four fully intelligent monitoring production lines, fully functional production, inspection, calibration, experimentation, high consistency standard requirements, ensuring high efficiency while polishing quality, maintaining progress, and demonstrating China's leading level in motorcycle production.

4 intelligent RGV production lines

50 fully automated robotic arms

Automatic frame and painting workshop

Annual output of 1 million sets